WhatsApp)

WhatsApp)

34 The European Journal of Mineral Processing and Environmental Protection Vol. 2, No. 1,, 2002, pp. 3439 Technical Note Why is the Bond Ball Mill ...

Simulation studies on Energy Requirement, ... efficiency of the mill can be ... kg of material was taken as feed for running the ball mill and bond index was ...

Electric motors monitoring: An alternative to increase the efficiency of ball mills556 Кб. Ball mills can be frequently found in ore grinding facilities.

efficiency of a ball mill Crusher South Africa ... and proposes a modification of the ball charge in order to improve the mill efficiency: Ball top size (bond ...

Plant performance improvements ... ball mill size distribution data showed ... that that CSE was the main contributor to the high Bond efficiency of the Dome ...

Effect of circulating load and classification efficiency on HPGR and ball mill capacity Alex Jankovic1, Walter Valery1, Birol Sönmez2 and Renato Oliveira2

ball mill efficiency equation pdf – SAMAC Crusher. ball mill efficiency Guideline Working Group of The Bond Equation. 3 Example SAGBall Mill Circuit WI Efficiency ...

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL PERFORMANCE Niyoshaka Nistlaba Stanley Lameck A dissertation submitted to the Faculty of Engineering and .

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is:

calculation of ball mill grinding efficiency cemnet. in literatures it is written that the grinding efficiency of ball mill is very less [less than 10%].

bonds equation crushing in South Africa ... Evaluate Grinding Mill Performance Efficiency Using Bond Work ... Bond Ball Mill Grindability tests ...

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ROOLVLRQ ... Additional power is required to keep the mill rotating. Power drawn by ball, semiautogenous and

Measuring ore grindability in balls mills. The Bond Ball Mill Work Index is a measure of the resistance of the material to grinding in a ball mill.

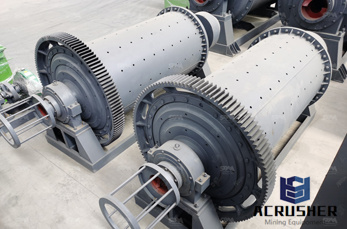

Grinding Efficiency In Ball Mill. ... High grinding efficiency ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

We have proposed that assessing ball mill efficiency be in terms of the energy for ... a dry ball mill showed the energy efficiency of ball mill comminution to ...

Ball Charge Loading Impact on Specific Power Consumption and Capacity. Grinding Media Size Gradation Another area of improving the grinding efficiency of a ball ...

It gives also a rough interpretation of the ball charge efficiency. Get the Service >> ... Essa Bond ball rod mill work index, abrasion index, impact test.

_Bond_EfficiencyGMSGICEv1r04 Determining the Bond Efficiency ... Wi Bond Work Index (kWh/t) WiBM Bond Ball Mill Test Work Index ...

1. Introduction. Ball mills are the most common and versatile type of tumbling mill. They are remarkable in that they can operate over a very wide range of conditions ...

China Ball Mill Efficiency Price Select 2017 high quality Ball Mill Efficiency Price products varied in Motor Type, Rotation Speed and Material from certified Chinese .

ball mill efficiency equation. Ball Mill ... In designing and optimizing a milling circuit using Bond Ball Mill Work Index[7], the following equations are used ...

bond ball mill efficiency ... Uniaxial compression test machine 3 STANDARD BOND TESTS The Bond 39;s standard ball mill is used to determine the work index value ...

Grinding in Ball Mills: Modeling and Process ... The design of a ball mill can vary significantly ... maximize the grinding efficiency due to their high density and ...

Bond Efficiency Slides Global Mining Standards. Feb 20, 2014 Meeting of Bond Efficiency Guideline Working Group of Circuit operating WI Example SAGBall Mill ...

WhatsApp)

WhatsApp)