WhatsApp)

WhatsApp)

Grinding Minerals design and manufacture a comprehensive line of grinding mills and entire grinding systems for mining, industrial minerals

Technische Woordenlijst Engels Nederlands, Free translation English to Dutch, Engineering Dictionary, vocabulary

Several of his books online, at Project Gutenberg.

Kaydon Bearings: slewing ring/turntable bearings and pinions. Four point contact, eight point contact, cross roller, three row roller.

SBB''s steel glossary is great for finding the definition for any steel term associated to the industry.

Web portal for buildingrelated information with a "whole building" focus provided by the National Institute of Building Sciences. Areas include Design Guidance ...

The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm and r = 50 mm, n c = rpm.

Thomson has a long history of manufacturing quality, strength, and expertise in all of its ball lead screw products.

LOREN COOK COMPANY: A leader in the design and manufacturing of fans, blowers, vents, laboratory exhaust systems, and energy recovery ventilators.

Sep 17, 2013· This video provides an overview of how to perform Critical Path Method (CPM) to find the Critical Path and Float using a ...

Derivation of critical velocity of ball mill Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable ...

Question Answers on Steam Turbines. What is important to remember about radial bearings? Answer: A turbine rotor is supported by two radial bearings, one on each ...

Good job! I like the inclusion of entropy. I had an entry planned, based on a the rotation in velocity space topic we discussed few weeks ago.

By Josh Wayner Josh Wayner''s taken it upon himself to challenge what everyone "knows" as far as barrel length, velocity and accuracy are concerned. According to ...

formula for finding critical velocity of ball mill, More details: Get the price of formula for finding critical velocity of ball mill: ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

ball mill critical speed formula – iron ore crusher, gold ore . Through ball mill critical speed formula, . CEMENT MILL FORMULAS MILL CRITICAL VELOCITY = 76 ...

Search Corporation company''s catalogues and technical brochures

Annapolis and Anne Arundel County high school and local sports, Navy sports, college sports, pro sports, sailing, boating, outdoors, golf, fishing, running and ...

derivation of critical velocity of ball mill – formula for finding critical velocity of ball mill – 14 Oct 2013 More details: Get the price of formula for finding ...

Critical rotation speed for ballmilling. ... Critical rotation speed of dry ballmill was studied by experiments and by numerical simulation ... velocity of ball i: v s:

TECHNICAL NOTES 8 GRINDING R. P ... can have a significant effect on the actual critical velocity. Mills usually operate in ... steel balls in a ball mill, ...

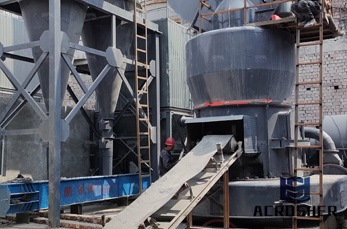

Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers

Consultants in occupational and environmental noise assessment, vibration and noise control engineering, structural dynamics, flowinduced vibrations, acoustic ...

WhatsApp)

WhatsApp)