WhatsApp)

WhatsApp)

Grinding is a finishing process used to improve surface finish, abrade hard materials, and tighten the tolerance on flat and cylindrical surfaces by removing a small ...

Concrete Grinding and Polishing | Benefits of Concrete Floor . Concrete grinding and polishing is the term used to describe the process of smoothing down rough ...

New grinding technology: Surface finishes of less than 1 RA . Oberg Industries has developed a process for the removal or cutting of any conductive material.

Tire Grinding Diamond Z Grinders . With twin motor horsepower ranging from 1,600 to 2,400 HP and 120 Lb. hammers, the Diamond Z Model 1463BT is the ideal machine ...

Dr. Jeffrey Badger is an expert in the industrial process of precision grinding. He works independently as a consultant, troubleshooting grinding problems and helping ...

Multiple diameters of industrial needles and shafts remain concentric using CNC Precision Grinding process. Quality Products, On Time, as .

HSM Form Grinding. Highspeed form grinding is one of our key core competencies. PGS is a leader in this unique process and specializes in form grinding complex ...

Electrochemical Grinding (ECG) Process Overview Electrochemical Grinding, or ECG, is a variation of ECM (Electrochemical Machining) that combines electrolytic

i Worcester Polytechnic Institute Signature Analysis of OD Grinding Processes with Applications in Monitoring and Diagnosis By Wei Tian A Thesis

What is the difference between lapping and grinding? Gear lapping or grinding will greatly improve the tooth profile of a gear. Learn more about the benefit

Surface Grinding is a manufacturing process which moves or grinding wheel relative a surface in a plane while a grinding wheel contacts the surface and removes a ...

Centerless grinding is the process of removing material from the outside diameter of a work piece using an abrasive wheel. In its simplest form, a centerless grinder consists of the machine base, grinding wheel, regulating wheel and work blade.

Basics of Grinding Fundamental Manufacturing Processes Video Series ... The Grinding Process Grinding is a material removal and surface generation process used to ...

advantages disadvantages grinding process. Nowadays, the XSM stone crusher(advantages disadvantages grinding process) in European style undoubtedly becomes the most ...

Throughfeed Grinding. Throughfeed grinding (also known as thrufeed grinding) is the process of feeding the part through the regulating wheel and the grinding wheel.

categories, emphasizing the approach for maximizing the grinding process for use of cubic boron nitride (CBN) abrasives.

Nov 05, 2012· Video embedded· For grinding precision round parts, this machine can grind both internal external diameter to very fine tolerances for steel, carbide, aluminium ...

part is not mounted, and the process can be automated. Centerless grinding also generates very tight tolerances with little difficulty. Figure 1.

Looking for grinding? Find out information about grinding. process by which surface material is removed from an object, usually metal, by the abrasive action of a ...

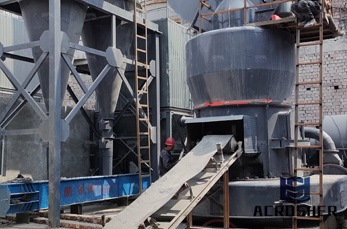

Grinding is an abrasive machining process that uses a grinding wheel or grinder as the cutting tool. Grinding is a subset of cutting, as grinding is a true metalcutting process. Grinding is very common in mineral processing plants and the cement industry.

KMT offers a wide range of grinding processes. Centerless grinding process. The CENTERLESS is the foundation stone of our reputation as a leader in precision grinding technology. Offering proven performance in infeed and throughfeed grinding for .

dry grinding process 300tph crusher Mine . 300tph rock crusher(dry grinding process),XSMAC machinery and equipment group attention crusher, sand .

Centerless grinding, an efficient manufacturing process, has been researched in detail in the past [16]. These covered the mechanism of roundness

Nov 19, 2008· Deep Six compilation was released March 1986 ). It was the very first release by C/Z Records, a few months .

WhatsApp)

WhatsApp)