WhatsApp)

WhatsApp)

Energy efficiency in cement manufacture. ... in particular raw material and cement grinding ... The increase in electricity consumption in the years following 2008 ...

Electricity power conservation in cement production ... Grinding, Drying, ... 37% of power consumption in cement plant

energy consumption in cement production Stone Crusher . Energy consumption. The cement industry is said to be an energy ... process for the fuel consumption and ...

The comparative advantages of ball mills and VRMs in cement grinding. ... The uncertainties ... specific electricity consumption and delivering consistent.

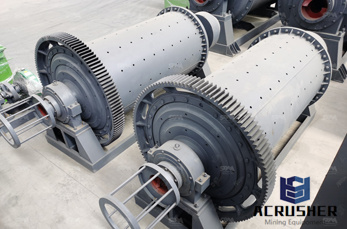

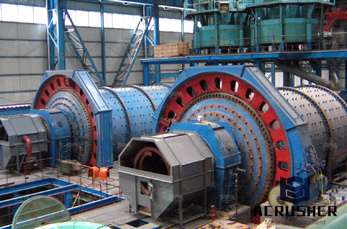

FL ball mill for cement grinding. Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives ...

In the cement grinding process, limestone, coal, ... Cement Industry End Use Electricity Consumption. Process. Machine Drive.%. Get Price.

o Generally 2/3 of the electricity consumed is used in the grinding of ... the total energy consumption of cement ... Ball mill improvements Maintaining grinding ...

Grinding trends in the cement industry Cement Lime Gypsum. Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency ...

Aug 25, 2011· Reduce Energy Consumption: Cement Production ... Nearly 70% of all electricity used in industry is consumed by some type of motor ... cement grinding.

grinding media consumption in cement wet ... Vertical cement mills mill the material in a roller mill with reduced electricity consumption ... Cement consumption ...

electricity consumption for grinding of opc in vertical roller mill. As a leading global manufacturer of crushing, ... cement grinding electricity consumption.

Cement Manufacturing Process Flow Chart Zenith Stone. Cement Manufacturing Process Flow Chart 70% of the total electricity consumption of the cement production ...

ELECTRICITY CONSUMED BY CEMENT PLANTS, BY PLANT PROCESS 1 ... Purchased : Total 3: Cement: consumption: Quantity: Quantity: Quantity: ... Grinding .

In the cement clinker production process, the material grinding power consumption accounts for about 70% of the overall power consumption directly affects the ...

cement grinding electricity consumption. It was assumed that power consumption in the finish grinding step ... cement grinding machine power consumption.

Improvement and Cost Saving Opportunities for ... Cost Saving Opportunities for Cement Making ... Specific fuel and electricity consumption per ton of cement ...

Iranian Fuel Conservation Company (IFCO) along with the Power Ministry in Iran has set energy consumption standards for different industries. For the cement industry ...

A critical review on energy use and savings in the cement industries use at different sections of cement industries, specific energy consumption, types of energy use ...

electric consumption cement grinding . ... Home Product The Processing Arrangement of 600,000 TPY Cement Grinding The Pro the electricity consumption of grinding ...

Reducing energy consumption of a raw ... Vibration increases electricity consumption, ... E. YigitOpen and closed circuit dry grinding of cement mill rejects in .

Energy Efficiency and Saving in the ... Large amounts of electricity are used grinding the ... which accounts for 74% of the energy consumption in global cement ...

grinding ball consumption in cement mills. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for ...

Saving Opportunities for Cement Making ... Energy Efficiency Improvement and Cost Saving Opportunities ... Final energy consumption in cement production by ...

Products by Application Engen. Engen is an Africanbased energy company focused on the refining and marketing of petroleum products and the provision of convenience ...

WhatsApp)

WhatsApp)