WhatsApp)

WhatsApp)

International Journal of Machine Tools Manufacture 43 (2003) 25–34 Stability of upmilling and downmilling, part 1: alternative analytical methods

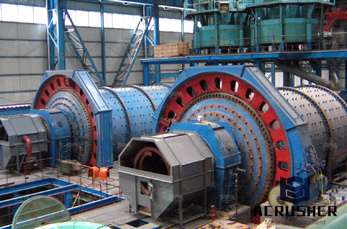

The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our ...

Up Milling And Down Milling, Wholesale Various High Quality Up Milling And Down Milling Products from Global Up Milling And Down Milling Suppliers and Up Milling .

Comparison between upmilling and downmilling operations on tool wear in milling ... focusing on the comparison of upmilling and downmilling operations .

Difference between up and down milling machine – . A milling machine is used to transform pieces of metal into multiple geometric shapes in which you desire.

Ultrasonic Wet Milling and MicroGrinding Ultrasonic WetMilling and MicroGrinding. Ultrasonication is an efficient means for the wetmilling and microgrinding ...

Many CNC machinists always use climb milling while many manual machinists always use conventional milling, but there are definitely advantages to using one versus the ...

When should you use Climb vs Conventional Milling? What''s the difference?

A milling machine is used to transform pieces of metal intomultiple geometric shapes.

down milling [′dau̇n ‚mil·iŋ] (metallurgy) climb cutting. Want to thank TFD for its existence? Tell a friend about us, add a link to this page, or visit the ...

up milling down milling F F Up vs down peripheral milling conventional face from ME 250 at Shanghai Jiao Tong University

Today we will discuss about difference between up milling and down milling. The milling is a machining process in which, a rotary cutter is used to remove the ...

Mechanical Engineering Assignment Help, up milling and down milling, table representing the differences between up milling and down milling

Down milling is also referred to as climb milling. The direction of cutter rotation is same as the feed motion. For example, if the cutter rotates ...

· Two types of end milling at partial radial immersion are distinguished in this work, namely; up and down endmilling. They are theoretically given ...

is a platform for academics to share research papers.

There are two distinct ways to cut materials when milling, conventional (up) milling and climb (down) ... CONVENTIONAL MILLING VS. CLIMB MILLING NUT LEAD SCREW

The milling machine''s knee rides up or down the column on a rigid track. A heavy, ... particularly for face milling operations requiring the facing of

Comparison between Upmilling and Downmilling Operations on Tool Wear in Milling Inconel 718 ☆

· There are some differences as listed below: For up milling the tool rotates against direction of feed and for down milling the tool rotates in the same ...

· Встроенное видео· Here is an animation which comperes two well know cutting methods in milling machines. Conventional Milling vs Climb Milling. https://

Milling cutters come in several shapes and many sizes. There is also a choice of coatings, as well as rake angle and number of cutting surfaces.

Milling is the machining process of using rotary cutters to remove material from a workpiece by advancing (or feeding) in a direction at an angle with the axis of the ...

HSMWorks allows you to specify when the tool should do up and down milling, or only one or the other. In the strategy specific parameter group on all 3D finishing ...

WhatsApp)

WhatsApp)