WhatsApp)

WhatsApp)

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

You know where a Jedd Gyorko home run ball belongs? That''s right, the Allegheny River. Disclaimer: You are leaving a Gizmodo Media Group, LLC website and going to a ...

Intro: Make a Ball Mill in 5 Minutes. This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or ...

both. One example is using a stirred ball mill such as an Attritor to perform the first stage of grinding and then achieving the final polishing grind with a

Jul 19, 2010· I think you''ve got it. Yes, you would have to add the .168 (Z position with chamfer touching hole) to the trig calculation to get the final Z value.

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

DYNO®MILL offers unmatched versatility in the comminution of suspended solids. models are available from liters to 600 liters

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

Split and easily detached, they are equipped with a special gasket held in tension by a special springloaded device, assuring a dusttight seal between mill ...

About Gulin. Looking for Information about Gulin? Visit for company news and careers as well as information about Gulin''s entire portfolio ...

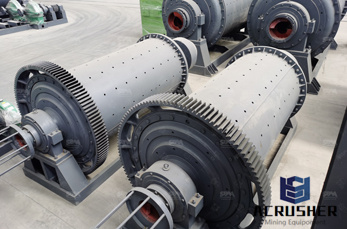

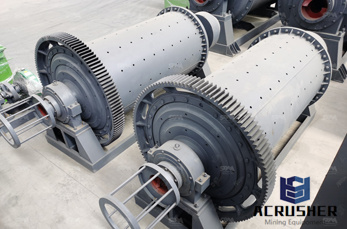

IV. BALL MILLS Ball mills are one of the more common mills and use a closed cylindrical container that is rotated horizontally on its axis so that the media cascades.

Hey, here''s lovable galoot Joel Embiid saying "Fuck LaVar Ball" on Instagram Live:

Product category Air Dryers SFD Bearings, Units, and Housings Condition monitoring Electric Motor specialist Linear motion Lubrication Solutions Maintenance products ...

Intro: Make a Ball Mill in 5 Minutes. This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or ...

Discover all the means used to grind your material in a mill on Magotteaux''s website. They are the only supplier offering a wide range of grinding media.

BibMe Free Bibliography Citation Maker MLA, APA, Chicago, Harvard

Jul 19, 2010· I think you''ve got it. Yes, you would have to add the .168 (Z position with chamfer touching hole) to the trig calculation to get the final Z value.

SKF designs and manufactures ball bearings for over 40 different industries using the latest bearing technology to provide customers a competitive advantage.

International journal of advanced scientific and technical research Issue 4 volume 1, JanuaryFebruary 2014 Available online on ...

Schaeffler Group Industrial 1 Contents Product Description 2 Ball Nuts 3 Load Rating And Life 4 Critical Speed And Buckling Load 5 Ordering Designations 6

Sep 17, 2013· Video embedded· This video provides an overview of how to perform Critical Path Method (CPM) to find the Critical Path and .

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

The Planetary Ball Mill PM 200 is an excellent choice when a high degree of fineness is required. Grinding down to the nano range. Read more.

WhatsApp)

WhatsApp)