WhatsApp)

WhatsApp)

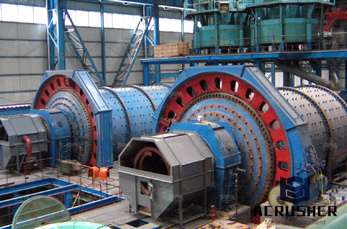

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell''s inside surface and no balls will fall from its position onto the shell. The imagery below ...

Supercond. Sci. Technol. 11 (1998) 1153–1159. Printed in the UK PII: S(98)933802 Effect of ball milling materials and methods on powder processing of Bi2223 superconductors M Yavuzy, H Maeday, L Vancez,HKLiuxand ...

jaw crusher, cone crusher, impact crusher, mobile crusher,grinding . iron ore ball mill in india. ball mill design is actually widely used . ball mill circulating load ball mill critical speed calculation ball mill design programs ball .

Do you want to show high speed ball milling or other products of your own company? Display your Products FREE now!

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs. ... Jar Rolling Mills ABBE Jar Rolling Mills are designed to support ...

Surfactantassisted ball milling: a novel route to novel materials with controlled nanostructure... 5 below this critical speed to keep the ball moving. Additionally, high speed yields high temperature that might contaminate the powder or ...

Herein, we report on the solventfree Sonogashira reaction utilizing high speed ball milling. Sonogashira coupling of a variety of para substituted aryl halides were performed with trimethylsilylacetylene or phenylacetylene. We observed ...

2014/05/21· めまれている· Ball mill, Grinding machine, Wet ball mill, Dry ball mill, Milling machine, Eric Zhang Add to Want to watch this again later? Sign in to add this video to a playlist. Sign in Share More Report Need to .

Planety Ball Mill PM 100 : RETSCH Milling Sieving Planetary Ball Mills are used wherever the highest degree of fineness is required. ... result in very high pulverization energy and therefore short grinding times. Planety Ball Mill PM ...

2015/06/19· めまれている· https:// Learn about Ball Mill Critical Speed and its effect on inner charge movements. The effect of Ball Mill RPM speed going from subcritical to supercritical helps ...

ball milling ball speed Simulation of ball motion and energy transfer in a plaary between the vial wall and ball, acts on the samples to be milled. As the driving speed increases, the Cori olis force (rotation bias force) forces the milling ...

I approached this project the patient way and started by first ordering the milling bible entitled "Ball Milling Theory and Practice for the Amateur Pyrotechnician" by Lloyd Sponenburgh. I have not faithfully followed his plan, nor do I ...

Ball Milling Equipment Porcelain Jars Internal Capacity PTA01 Model Ball Mill Wheel Attachment Fits on the VLWhisper or RKWhisper with a 12" wheelhead Ball mills have been used for decades to grind and mix materials used ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed. Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant.

Influence of Combination of Ball Diameters and Rotation Speed on Grinding Performance of Alumina by Ball Milling [in Japanese] KONDO Yoshihito, .

めまれている· At some point in this pyroart adventure, we start to hear or get the feeling, that we need a ball mill to grind chemicals very fine or to make highquality black powder. This project will not attempt to be a comprehensive review of ball ...

Bigger size media has more crushing effect as well as smaller sizes better grinding effect. Rotation speed of the ball mill is also one of the factors changing thenbsp » Learn More effect of speed in ball milling. torque on the driving ...

The 12 Principles of Green Chemistry Prevention of waste Atom Economy Less Hazardous Chemical Syntheses Design Safer Chemicals ... Types of Ball Mills Drum ball mills Jetmills Beadmills Horizontal rotary ball mills Vibration ball mills

STUDY ON THE EFFECT OF HIGH ENERGY BALL MILLING (A NANO MATERIAL PROCESS) ON THE MICROSTRUCTURE AND MECHANICAL PROPERTIES OF A (AlSiFeCu) ALLOY A THESIS SUBMITTED IN PARTIAL ...

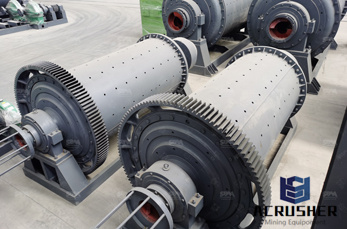

rotation speed, type of milling (wet or dry) as well as the size of the steel balls [3]. Mills are also one of the largest energy consumers in processing plants which can be estimated to about 50% of the total energy utilized in ...

Ball Mill Torque Speed Curve | ore crushing machine XSM Ball Mill Torque Speed Curve in the word,We can give you best (Ball Mill Torque Speed Curve low price cost),if you have any question welcome you click the icon on .

Critical rotation speed of dry ballmill was studied by experiments and by numerical simulation using Discrete Element Method (DEM). The results carried out by both methods showed good agreement. It has been commonly accepted ...

"Mining equipment used in drilling, crushing or grinding of various minerals are put to the test and may require more than one rehabilitation before being turned ... What is a Ball Mill? A ball mill is a type of grinding mill, purposed ...

Haypi Monster derivation of critical speed of ball mill Sep 10, 2013 ... Ball mill critical speed, ball mill efficiencyWhat is the ball mill critical speed ... to improve ball mill efficiency ? ball mill critical speed calculation... critical speed ...

WhatsApp)

WhatsApp)