WhatsApp)

WhatsApp)

Variability of Portland cement. Portland cement variability can occasionally cause problems. "Are all nominally similar cements the same?" "Does cement from the same ...

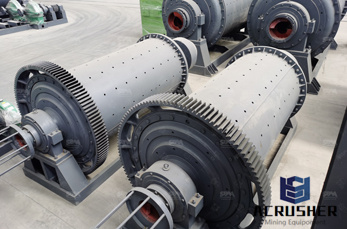

Whether ball mill or vertical roller mill (VRM), A TEC offers the expert solution for efficiency optimization to increase mill productivity and/or reduce mill power...

Dry, semidry, semiwet and wet processes are the four main process routes that are used for the production of cement. Dry processes are considerably more energy ...

how to increase the production of ball mill. Cement Equipment Production Lines . The main cement production equipment include crusher, ball mill, ...

Composition of cement. Introduction Portland cement gets its strength from chemical reactions between the cement and water. The process is known as hydration.

Home Business The Best Way to Gain Efficience of Cement Mill. ... manufacturers are exploring the effective way to increase production and save energy of cement mill.

Cemex Philippines to increase cement production. Cemex Philippines to increase cement production. ... Cemex opens new Philippines cement mill.

Environmental, Health, and Safety Guidelines CEMENT AND LIME MANUFACTURING APRIL 30, 2007 3 WORLD BANK GROUP • Storage of waste derived fuels in areas .

Aims to improve cement and concrete and its uses, and raise the quality of construction. Page includes industry news magazine.

Above: Summary data for the United States of America and its cement industry. Cement Rotary revolution. It was in the early 1900s however, that cement production ...

See our Powerpoints on tire incineration. What is "Tire Derived Fuel" and why is it dangerous? As of 2003, about 290 million tires are discarded in the every ...

In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stage. As a kind of raw material mill ...

the home of International Cement Review, the world''s most requested magazine in the global cement industry. Leaders in News, Conferences, Training and ...

Cement mill. Cemax full range of cement grinding aids and performance enhancer, formulated to increase cement mill throughput, reduce cement production cost and ...

Aggregates are inert granular materials such as sand, gravel, or crushed stone that, along with water and portland cement, are an essential ingredient in concrete.

November 11 2016 Giant Cement Holding joins the Elementia Cement Division. This acquisition is key, because it will increase production and marketing, by extending ...

•Availability of funds 4 CASE STUDY Holtec had carried out a plant operations audit in a dry process cement plant operating at a capacity of about 3,350 tpd clinker.

The potential opportunities for improving energy efficiency and lower CO 2 emissions in raw material generation and production of concrete are smaller than in cement ...

to increase production in cement ... how to increase production from ball mills Grinding Mill how to increase production from ball mills. how to increase the ...

Loesche has provided a LM 56 3+3 CS vertical roller mill to Attock Cement Pakistan Ltd, for the grinding of cement clinker. The new mill will be used in the new line ...

Though "cement" and "concrete" are often used interchangeably, concrete is actually the final product made from cement. The primary component of cement is ...

Ball mill as a kind of popular grinding and ore beneficiation equipment is widely used in cement ... the most direct way to increase Raymond mill production; ...

Advanced process control for the cement industry ... • Up to 36% increase in production ... the mill. Benefits • Up to 6% increase in production

CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Minerals Process Technology AsiaPacific, Brisbane, Australia email:

WhatsApp)

WhatsApp)