WhatsApp)

WhatsApp)

Ball mill,price,cost,specification,design capacity 5 TPH for. Gulin Least News. Optimizing manganese ore sinter plants: process parameters and design implications ...

All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material.

What is a Ball Mill? A ball mill is a type of grinding mill, purposed similarly to the sag mill or other mining crushers. These machines are used to grind or mix ...

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

Ball Mill grinds material by rotating The ball grinding mill is with stable and Ball mills are the key equipment for grinding after the crushing process,

grinding process in ball mill; grinding process in ball mill. Grinding media sorting and balls Magotteaux. Grinding media. Grinding balls are only one type of ...

Grinding millsBall millsBall grinderBall grinding . Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials ...

Ball Mill. Ball mill as most common grinding equipment, play an important role in crushing and mining industry. It can be helpful in the process of metallic powders ...

grinding process of cement mill [ 5564 Ratings ] The Gulin ... Ball grinding mill, coal, fly vertical roller mill for cement factory process flow., ...

Grinding Process of Ball Mill. Overview on the grinding mills and their dual pinion mill drives .5'' ball mills will be briefly . The grinding process with one 34'' x ...

Used Ball Mill Machine Capacity in Indonesia,Grinding Ball Mill 2 days ago ... but the grinding process and uses, or differentiated, rod mill use ...

NEUROCONTROL OF A BALL MILL GRINDING Resec Mar 16, 2013 ... The paper presents an overview of the current methodology and practice in modeling and control of .

Ball Mill Grinder Machine Grinding and Milling | FAB 3R, Semiautogenous (SAG) mills, rod ''s comminution solutions include Autogenous (AG) mills, ball ...

Dry ball mill is the key equipment for grinding after the crushing process, ... cement grinding ball mill manufacturer in india Crushers Price Sep 17, ...

Process. 48(2), ... The optimal ball diameter in a mill 333 ... The first order kinetics of grinding occurred for all ball charges and for

Grinding media. Grinding balls are only one type of grinding media. ... in a mill. Grinding media sorting is performed when the ball load wears out. ... Grinding process.

... on the original ball mill pulverizing process using high... Coal Pulverising in Boilers ... Coal Ball Mill/Grinding Mill Taida Mining and

Closedcircuit systems. The efficiency of the early stages of grinding in a ball mill is much greater than that for formation of ultrafine particles, so ball mills ...

Beneficiation ball mill has three influence factors in the grinding process with medium, including the ore properties, the structure of and the operation conditions ...

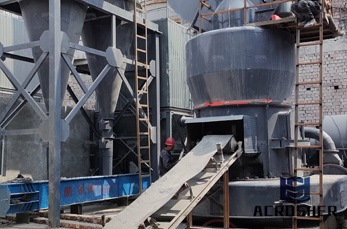

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

Haypi Monster Cement Grinding Mill Processing0 Flow Diagram Iron slag process flow. Known conditions: Raw Material: Iron slag. Raw grade of copper ore: around 5%8% ...

51 BULGARIAN ACADEMY OF SCIENCES CYBERNETICS AND INFORMATION TECHNOLOGIES • Volume 12, No 2 Sofia • 2012 Grinding in Ball Mills: Modeling and Process Control

SAG is an acronym for SemiAutogenous Grinding. SAG mills are essentially autogenous mills, but utilize grinding balls to aid in grinding like in a ball mill.

Stirred ball mill grinding is an important process in reducing the size of ceramic micro ... Experiments performed with TiO2 suspended in ethylene glycol are used.

WhatsApp)

WhatsApp)