WhatsApp)

WhatsApp)

Optimization of mill performance by using online ball and ... saimm. conditions such as mill speed or balls filling degree, should limit the risk of projection ...

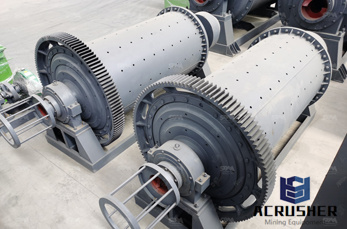

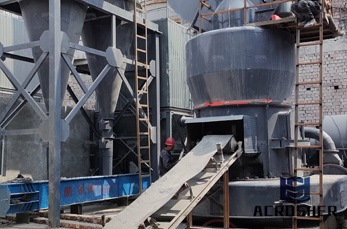

Autogenous, semiautogenous and ball mills for wet and dry grinding Autogenous and semiautogenous mills. / Ball mills. / Rod mills. / slaking

Ball mill ball charge degree of ball filling calculation

Jan 07, 2017· How to Make a Ball Mill. ... You can fill the container with as much of the substance to be ground as you''d like.

Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials ... please feel free to fill out the form below, ...

Sep 16, 2008· Video embedded· How to refill a Chef''n Pepper Grinder ShabbirSafdar. Loading ... Chef''n Black Clear Dual Pepper Ball ... How to Fill and Adjust a Pepper Mill ...

Axial transport in dry ball mills. Author links open ... At first increases and then decreases with increasing mill fill level due to the competing effects of ...

Lime Slaking Westpro Machinery. The actual lime slaking process is performed either in a detention slaker or in a ball mill type slaker. ... automated, controlled ...

How to Use a Ball Mill Safely and Effectively I have some lump charcoal that just came out of my retort after I cooked it, and I want to turn it into airfloat charcoal.

Henan Bailing Machinery CO.,ltd. is a professional manufacturer of ball mill. More information about ball mill ... Ball mill (also named grinding ball) ... fill in ...

The platform of the ball mill consists of a wooden base with a pulley slot, ... then remove the container lid and fill the container with steel balls.

excessive presence of ball scats. The balls are of the cast semisteel ... The ball load in the mill, prior to the removal of the scats, was calculated

We can calculate the steel charge volume of a ball or rod mill and express it as the % of the volume within the liners that is filled with grinding media. While the ...

noise level measurment for coal ball mill XSM is a leading global manufacturer of crushing and milling equipment ... Smart Fill | Ball Mill Level RTD ...

Most cement is currently ground in ball mills. Cement clinker is usually ground using a cement ball mill. ... You can fill out the form below and submit your ...

Mini Planetary Ball Mill is an ideal facility to acquire research samples for research institutes, universities as well as enterprise laboratory which needs to ...

Aug 03, 2016· Video embedded· wet ball mill calculations for fill volume Wet Ball Mill Calculations For Fill Volume,ball mill dynamic load ... ball mill volume calculation .

MACSALAB Rod / Ball Mill Vessels are available in ... Try to limit the size of the batch to 25% of the total vessel volume which is sufficient to fill the voids and ...

Investigation on measuring the fill level of an industrial ball mill based on the vibration characteristics of the mill shell

Roller Mill For Fill Cellulose; ... Applications Of Ball Mill. ball mill application,ball mill technology,ball millsHenan ...

Ball mill fill level electronic ear location. In Single chamber ball mill for clinker grinding what is optimim locaion for electronic ear for measuring ball mill fill ...

method to measure the fill level of the ball mill. Investigation on measuring the fill level of an industrial ball mill based on the vibration characteristics of the ...

A typical ball mill has an L/D ... A good starting point for material loading is to have enough material in the mill to fill all of the voids and just cover the ...

The ball mill is a key equipment to grind the crushed materials, ... If you have some questions about our products, please feel free to fill out the form below, ...

WhatsApp)

WhatsApp)