WhatsApp)

WhatsApp)

Pendulem Grinding Mill Calculations. calculations to be made in a chute feeder ball mill ... Home inlet chutes to vibratory feeders ball mill inlet design vibrating ...

is home to a collection of both free and subscriptionbased calculation tools to aid metallurgical process engineers perform comminution calculations.

ball mill design calculations Coal Surface Mining. ball mill design calculation in mining project – 29 Oct 2013 ... Design Calculations For Ball Mill.

16 Ball Filling Degree Mill Calculation. ... Filling Degree Calculations Mill In / Outlet Filling Degree Internal diameter Free Height Diameter ... ball mill design.

Raymond Mill Capacity Calculations. herozintal ball mill calculation. Ball Mill Critical Speed Calculation – Raymond Grinding Mill. Ball mil design calculation? ...

Calculation of energy required for grinding in a ball mill. ... Calculation of Energy Required for Grinding in a ... of energy required for grinding in a ball ...

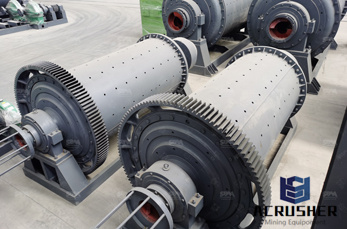

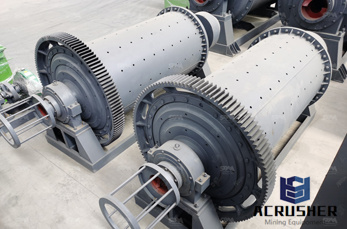

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index ...

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is:

Ball Mill Design Calculation Xls And PDF File; ... Flange Design Calculations Adjacent vessel shapes ... MILL DESIGN, MILL DIMENSIONS . * Other Ball Mill Dimensions ...

Calculations for mill motor power, ... To calculate the motor power required for a cylindrical type ball mill, ... buy Adobe Creative Suite 3 Design Premium license;

Documents Similar To ball mill calculations Skip carousel. 16 Ball Filling Degree Mill Calculation. Ball Mill Charge. Ball Mill Design by Dem.

Grinding in Ball Mills: Modeling and Process Control Vladimir Monov, Blagoy Sokolov, ... The design of a ball mill can vary significantly depending on the size, the

gy of the balls that has a large effect on the grinding. Rocking mills (ball The physical constants used in these calculations Design Method of Ball Mill by.

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

SUMITOMO KAGAKU 2007II 2 Design Method of Ball Mill by Discrete Element Method of the balls are in a state where they are covered with the solid materials.

22K Yu Deng structural design calculation for vibrating screen First check the design calculations, if possible, ... ball mill manufacturers in kolkata india;

ball mill design calculations. More information about mineral machine, Consult our staff. A brief history of feedback control Chapter 1 . This page hosted by ...

Design and Optimization of Ball Mill for ... The performance of ball mill ... to carry out set of calculations to quantify ball mill design parametersto reduce ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

The mill sizing page: Please find below two calculators for sizing mills using the Bond and Rowland methods: Ball mill sizing: Calculator for ball mill(s) in a single ...

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

Choosing a SAG Mill To Achieve Design Performance John Starkey1, Principal Consulting Engineer Sami Hindstrom2, Manager, Grinding Travis Orser2, Project Manager, Grinding

Ball Mill Design Calculation IMPACT ON GRINDING MILL DESIGN OF RECENT NEW DISCOVERIES Table 2 ?Typical Mill Design Calculations CASE 1 ?No pebble ...

2 MODELLING THE SPECIFIC GRINDING ENERGY AND BALLMILL SCALEUP Ballmill scale up (Bond''s Law) Data: zBond work index w i zFeed D f and product d size (both .

WhatsApp)

WhatsApp)