WhatsApp)

WhatsApp)

Dry, semidry, semiwet and wet processes are the four main process routes that are used for the production of cement. Dry processes are considerably more energy ...

Whether ball mill or vertical roller mill (VRM), A TEC offers the expert solution for efficiency optimization to increase mill productivity and/or reduce mill power...

industrial case study: the cement industry calmac study id: final report prepared for pacific gas and electric company san francisco, california

Manufacturing and exporting of sand mills, open type sand mills, steel ball mills, sigma kneader, batch type blenders, open type sand mills, closed type sand mills ...

Earle''s cement plant: Hope, Derbyshire ... Picture: ©English Heritage NMR Aerofilms Collection. Catalogue number R20367.

This section does not cite any sources. Please help improve this section by adding citations to reliable sources. Unsourced material may be challenged and removed.

Ball Mill In A Cement Plant : The general mining methods are surface mining, while some silicates, such as sand, are commonly mined using dredges, from lakes ...

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

Grinding media. Grinding balls are only one type of grinding media. Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill.

Cement history, in brief, from the Greeks and Romans to the development of Portland cement

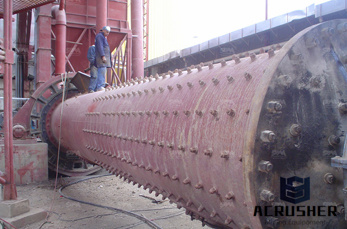

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

Early Ribblesdale Castle Brand. The image of Clitheroe Castle eventually gave its name to the Castle Cement group.

coal hammer mill design[crusher and mill] Hammer Mill Design Mini Project – Free download as PDF File (.pdf), text . The basic design of the industrial hammer ...

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

•Availability of funds 4 CASE STUDY Holtec had carried out a plant operations audit in a dry process cement plant operating at a capacity of about 3,350 tpd clinker.

How is cement manufactured? Learn cement manufacturing process thoroughly.

Module: 5 Lecture: 24 Cement industries Dr. N. K. Patel N P T E L 163 Comparison of dry process and wet process Criteria Dry process Wet process

A wide selection of ROLLER MILLS available. Call us for more details.

Specialized foundry of premium wear parts for aggregate, recycling, mining and cement plants. Blowbars, cones, jaws, liners, kiln inlet, cooler grates, ceramic insert ...

Job Interview Practice Test Why Do You Want This Job? Answer this job interview question to determine if you are prepared for a successful job interview

Manufacturing and exporting of ball mill, industrial ball mill, ball mills, industrial ball mills, shrouded ball mill, enamel dispersion mill, primer dispersion mill ...

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles.

GRINDING MEDIA FOR THE VARIATIONS IN CEMENT MANUFACTURING. Changing impact conditions can cause conventional grinding media to either work harden or cause .

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

WhatsApp)

WhatsApp)