WhatsApp)

WhatsApp)

See what is involved in the polished concrete process. ... to fourstep process. The next steps involve fine grinding of the concrete ... ConcreteNetwork ...

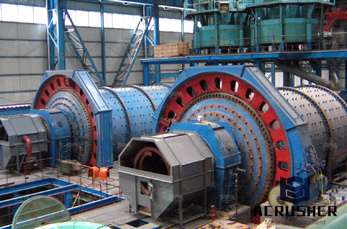

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

Cement grinding Vertical roller mills versus ball ... Grinding process ... Dehydration of the gypsum added to the cement In the grinding process heat will be ...

THR Concrete Grinding''s two step process offers the fastest, most affordable trip hazard repairs, a permanent solution to problems such as raised walkways and raised ...

Cement is the basic ingredient of construction and the most widely used construction material. Its manufacturing includes extraction, proportioning, grinding,

The cement clinker grinding plant or cement grinding station acts as an individual production line in the last period of the cement production process ...

are now in demand as plain surfactants for the grinding process, under targets based on a minimum price and ... the efficiency of the cement molturation process, one

Brief description of a cement mill. ... Clinker grinding uses a lot of energy and the cement ... way to get a clear picture of a complex process like cement ...

Portland cement is the most common type of cement in general use ... This is achieved in a cement mill. The grinding process is controlled to obtain a powder ...

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL ... cement plant The benefits that can be achieved due to the optimisation of cement grinding system through process

ppt cement manufacturing process Gold Ore Crusher. Department of State – Venezuela. They are in the process of being replaced by Fact Sheets that focus on US ...

In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stage. As a kind of raw material mill ...

A cement mill (or finish mill in ... The recent history of the technology has been mainly concerned with reducing the energy consumption of the grinding process ...

Coal in the cement industry Welcome To Auroma Coke Limited · PDF . Coal in the cement industry Cement manufacturing consists of raw meal grinding, blending ...

Cement Making Process (Interactive Animation) PCA

CGM Cement mill, cement Grinding mill for cement Grinding process in cement plant. Ball mills and vertical mills are the best choice for your cement Grinding plant.

For cement grinding processes with different types of cement, efficient changeover between products is ... advanced process control. ...

Cement Crushing Grinding Plant. ... In cement production process, cement crusher is very important since most of the raw materials will have to be crushed before ...

Process Optimization in Cement Industry Download as PDF File (.pdf), Text File (.txt) or read online.

Cement raw materials processing plant. ... in the dry cement production line, the grinding process accounts for over 60% of the factory''s total energy consumption.

The Pavilion8 Cement Grinding Application offers process and quality control independent of system faced with a traditional ball mill circuit ...

WET GRINDING AND DRYINGGRINDING OPERATIONS , of cement raw meal grinding as in Fig 17/1, sieve residues R(O09) and R(O063) are presented as .

Optimization of Cement Grinding Operation in Ball Mills. ... The graphical analysis in Figure 1 represents the progress of the grinding process along the length of ...

The use of a good Cement clinker grinding aid can be vital in today''s increasing material demands. Along with the obligation to process increasingly larger ...

WhatsApp)

WhatsApp)