WhatsApp)

WhatsApp)

Environmental, Health, and Safety Guidelines CEMENT AND LIME MANUFACTURING APRIL 30, 2007 3 WORLD BANK GROUP • Storage of waste derived fuels in areas .

Composition of cement. Introduction Portland cement gets its strength from chemical reactions between the cement and water. The process is known as hydration.

We produce a wide range of highalumina cements and calcium aluminate have customers in more than 60 countries around the world.

Blue Monster ® Microbubble Leak Detector. MillRose Blue Monster ® Microbubble leak detector is a sensitive solution formulated to detect even the smallest of leaks ...

Megatech Supplier of mini cement plants, industrial mini cement plants, cement making machines, industrial cement plants, vertical shaft kiln machine, industrial ...

Supplier of a curated selection of natural stone, porcelain tile, and engineered stone for architects, designers, developers, contractors homeowners.

Arklay S. Richards is a leading manufacturer of industrial thermocouples, anemometers and wind Speed sensors including metal ceramic temperature sensors.

Cement manufacturing process components of a cement plant from quarry to kiln to cement mill.

Portland cement is the basic ingredient of concrete. Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden ...

In the manufacture of Portland cement, clinker occurs as lumps or nodules, usually 3 millimetres ( in) to 25 millimetres ( in) in diameter, produced by ...

Product d ata Sheet ceMeNt Lafarge PortLaNd ceMeNt Lafarge Portland Cement is a high quality, costeffective basic building material used in virtually all forms of ...

Evaluating cement bond. Acoustic logs do not measure cement quality directly, rather, this value is inferred from the degree of acoustic coupling of the cement to the ...

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction ...

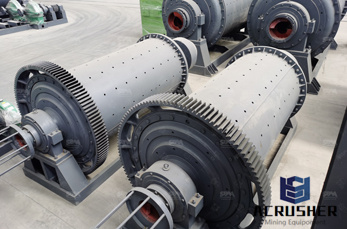

Ball Mill In A Cement Plant : The general mining methods are surface mining, while some silicates, such as sand, are commonly mined using dredges, from lakes ...

Now that we are seeing cold weather, are there any restrictions on plastering at lower temperatures? Can installation in too low a temperature be problematic for any ...

Manufacturing the cement kiln. Most Portland cement is made in a rotary kiln. Basically, this is a long cylinder rotating about its axis once every minute or two.

2 Depending on the origin of the raw materials used and the clinker production conditions, cement contains up to 30 ppm hexavalent chromium (chromate).

Calcium aluminate cements are cements consisting predominantly of hydraulic calcium aluminates. Alternative names are "aluminous cement", "highalumina cement" and ...

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

The most comprehensive technical information regarding the hose industry Steam Temperature Pressure Conversion Guide. Technical Reference Technical Literature ...

Aug 10, 2017· Cement itself is produced by heating limestone with small amounts of other ingredients such as clay. The mixture is brought to a high temperature in a kiln ...

How Cement is made at Continental. Cement is made from common materials such as limestone, clay, silica, and iron ore. Principle raw materials are a blend of 88% ...

See our Powerpoints on tire incineration. What is "Tire Derived Fuel" and why is it dangerous? As of 2003, about 290 million tires are discarded in the every ...

WhatsApp)

WhatsApp)